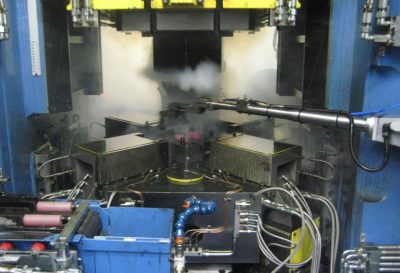

High-pressure die lubrication system: it allows to dose perfectly and consistently the necessary amount of lubricant, thanks to the graduated scale on the lubricant opening knob, thus avoiding costly waste.

The range scale can be used as a reference in contracts for the immediate adjustment of the amount of lubricant avoiding waste of time for settings and production waste due to wrong dosage. The system allows the use of the richest mixtures in graphite up to 1200 CST 40 ° C greatly improving the quality of forged material.

The pump positioned in the tank, allows to always obtain the steady suspension mixture of oil, in addition the container is equipped with an additional manual stirrer hooked to the lid.

The perfect oil batching significantly improves the duration of the die for what concerns sedimentary deposits of oils (with lower density for sandblasting).

The excellent flow rate of oil evaporation valves allow efficient cooling of plugs placed on drilling tools enabling better flows and long duration.

If properly adjusted the dosing system saves 25% -30% of the normally used lubricant quantity.

Die lubrication systems